Advanced Manufacturing Capstone

The Advanced Manufacturing (AM) Cluster at the Faculty of Applied Sciences and Technology (FAST) completed various capstone projects across its four programs in the 2018/2019 academic year, building on programs’ strengths in design, manufacturing and automation systems and collaborating with partnerships to address current industrial challenges.

The AM cluster in FAST forged the real world challenges presented to the Faculty by the industrial partners into capstone projects in which the students apply knowledge and practical skills acquired during their time at Humber to formulate a solution and develop innovative prototypes.

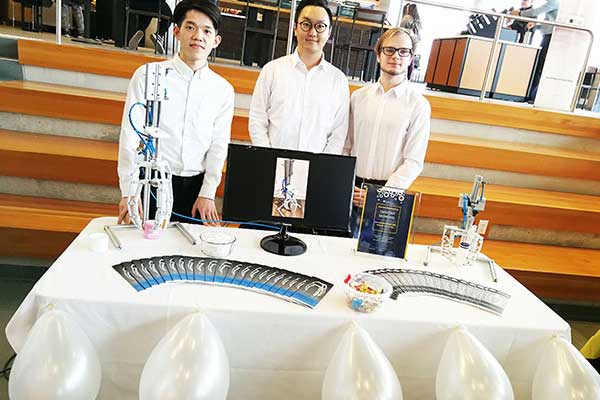

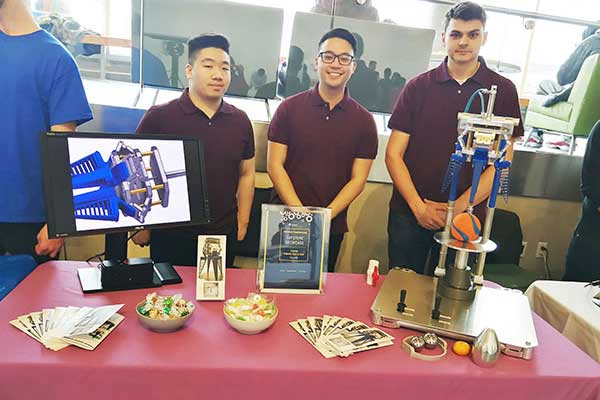

Students in their 6th semester of Mechanical Engineering Technology Program worked on eleven different industrial projects, each project was taken up by a group of three or four students. The projects focused on application of advanced manufacturing techniques to address industry challenges, aimed at increasing efficiency, safety and / or product quality. Project areas varied between nuclear, power, manufacturing, medical, and renewable energy. In addition to the technical value of the projects, students got a chance to go through a full cycle of real projects, enhancing their skills in scoping, planning, resource management, design, fabrication, test, and producing professional engineering documents. Industrial partners including ABC, AMAG, Mersen, collaborated with faculty and students during this process to ensure the outcome of projects were scalable in their facility and address requirements.

The students in the Electromechanical Engineering Technology Program engaged in full year group Capstone projects. The students began with brainstorming sessions to come up with an idea for an automation centric project, then proceeded to flesh out their ideas with preliminary designs, budgets and schedules. Once approved, the projects were then built, tuned, and presented along with complete documentation and engineering drawings. Using PLCs, robotics, electrical and pneumatic systems, the projects covered a wide range of automated manufacturing industries and challenges. Some projects were sponsored by Industry partners such as an Automated Guided Vehicle with SEW-EURODRIVE, a Kuka collaborative robot, a Blow Mold Vent Channel Remover with ABC Group and a Process Control Check Fixture with Nahanni Steel. These Capstone projects are an excellent opportunity for the students to integrate their 3 years of learning at Humber into one culminating display.

Watch this video to to check out the amazing work of Humber students in Electromechanical, Electronics and Mechanical Engineering Technology